We guarantee a CLEAN PROFIT!

– Saving over 90% *

– 2-5 years return on investment in boiler room up to 20 years! **

– Independence of fluctuations in fuel prices

Using expensive fuel every day, your money “goes with the smoke”.

*Compared to the fired boiler I had coal, the final result depends on the size of the investment

** Data from users of MetalERG boilers and from Danish sources

The installation and operation of straw boilers is fully profitable.

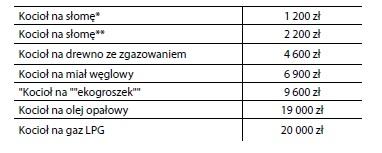

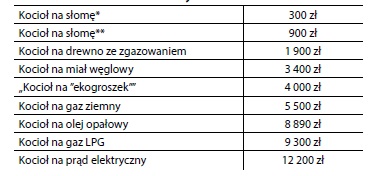

Savings in daily heat generation depend on the current energy source and are from 60% (in the case of wood) to over 97% (in the case of electricity). Detailed calculations are presented in the following examples. In addition, for each customer, we can perform calculations based on individual data! 4> Calculation for low power boiler

Sample calculations for heating a 180 m2 detached house with moderate building insulation.

Calculation for average power boiler

An indicative comparison of the heating costs of a wholesaler is about 800m2

Calculations for the heater 2000 kW

Return on investment – boiler for straw and heaters

Based on technical data and feedback from our customers, we can estimate the return on investment for the period from 1 season to a maximum of 5 years. The rate of return depends on the size of the boiler room and the intensity of boiler operation, the amount of coal replaced, the amount of oil and gas, the price of straw, etc. Below are some examples. We can also estimate the return on investment for a particular new installation – call us And see how fast you can start earning money on heating.

How long does it take to buy a boiler for a straw? See our examples:

Farm – Chrzelice

Farmer from Chrzelice village in Opole (own straw) – Mr Tadeusz Tarach – has been operating the EKOPAL RM 30 boiler for eight seasons, he says that his investment has already been returned to him within three years. This boiler heats two houses with a total area of 750 m2.

Cooperative Agricultural Cooperative in Świerkówki

The President of the Cooperative Agricultural Cooperative in Świerkówki (Wielkopolska province), where the EKOPAL RM 02 boiler is installed, states that his investment has already been repaid within 2 years. The boiler is fired with its own straw.

At the Primary School No. 2 in Milicz (Lower Silesia), 3 EKOPAL RM 02 boilers (total power of 1.200 kW) were installed in 2000 by MetalERG.

According to the director of this school during the heating season, when the school was heated by the heat from the city coal boiler, heating fees amounted to about 260,000 zł, while the cost of operating the boiler room for straw (including the purchase of straw at farmers) amounted to only about 60,000 zł. Expenditures for the construction of the boiler house will also be paid within 4-5 years.

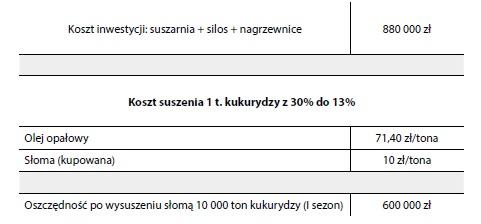

Seed Headquarters in Kluczbork

Mr. Jan Mierzwiak, President of the Head Office in Kluczbork – in which EKOPAL S heaters are used, declares that the cost of the investment has already been paid after 1 season of drying.

Durability of boilers on straw

Boilers for straw are characterized by greater durability than coal boilers, since straw has much less sulfur to destroy boilers than coal. The oldest boilers produced by MetalERG have been in operation for 16 years, and Danish experience shows that straw boilers are operated for up to 20 years (everything depends on boiler handling, straw humidity, etc.).

The quality of the product is of vital importance for the life of the boiler (apart from the quality of the fuel used). At MetalERG we attach great importance to quality – it has been building on our brand for many years and thanks to it we systematically increase the number of regular customers. For the construction of boilers we use boiler steel, which guarantees the durability and reliability of the products. We will be happy to communicate with our clients who will talk about it. We also invite you to our headquarters in Oława, where you can see the production process of boilers.

See also: